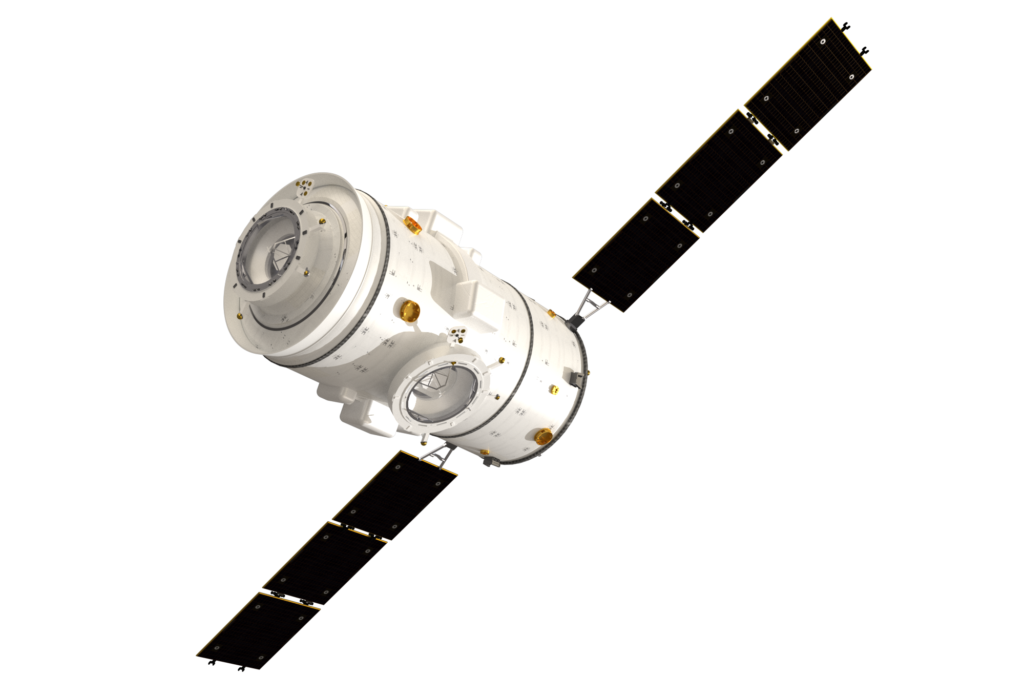

Searching for High-resolution Volatiles: Lunar Trailblazer Illustration (credit: Lockheed Martin Space)

In the 1800s and 1900s on Earth, you made your fortune if you discovered a new petroleum source. More colorfully spoken, “Striking it Rich!” was the subject of movies, such as 1956 Giant and the television series The Beverly Hillbillies. The competition is heating up for the discovery and capture lunar resources due to the new space race there. Aside from its symbolic value, water can enable life and be used for in situ fuels and other materials. What progress has been made to find and utilize lunar water? Water on the moon might be even more valuable than petroleum on Earth.

SustainSpace has covered water use and recycling on the International Space Station (ISS) in NASA Targets Reduced Water Usage for Long Duration Missions (2014 and Airbus ESA Advanced Closed Loop System (ACLS) (2018), etc. Some of that technology can be used on the Moon. Yet what is new?

Water on the Moon

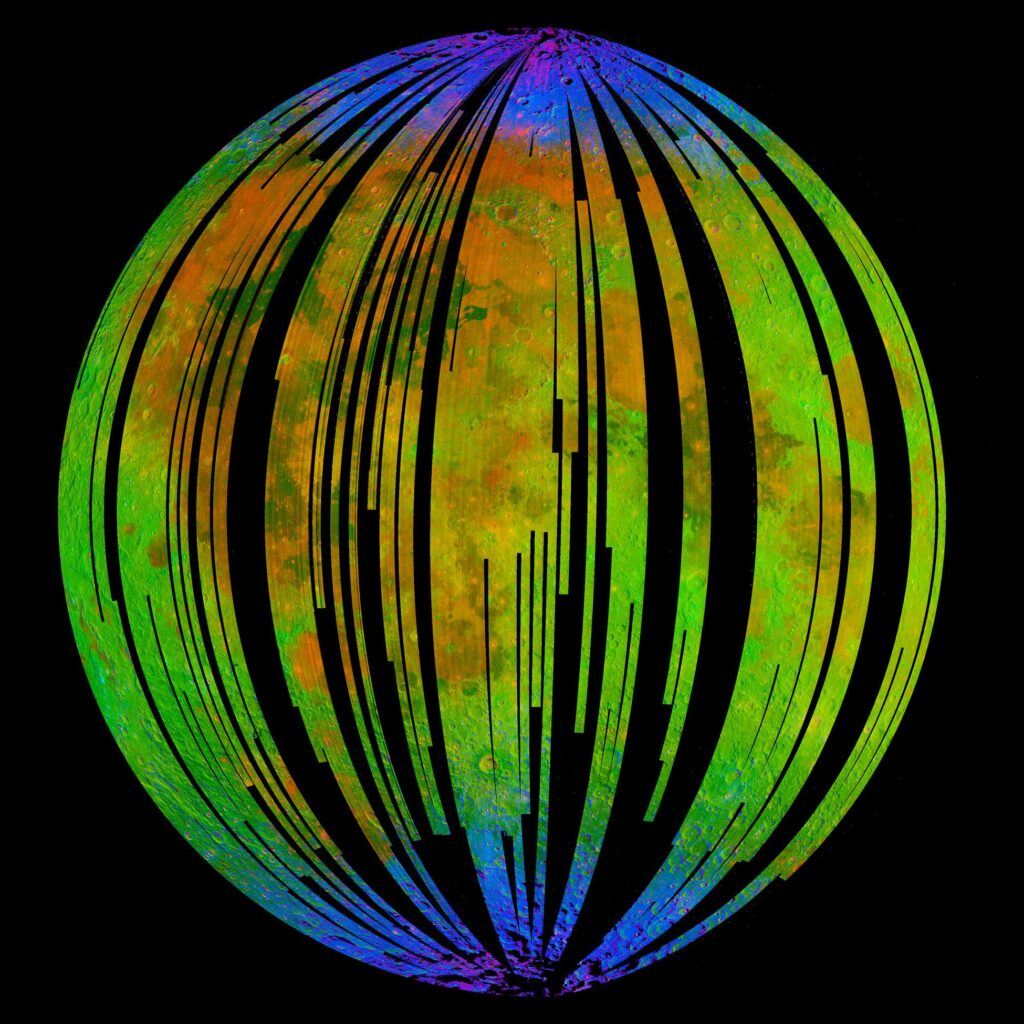

Results from NASA’s 1994 Clementine mission suggested there was ice in a permanently shadowed region of the Moon This claim was confirmed by the 1998 Lunar Prospector mission which found that the largest concentrations of hydrogen exist in the areas of the lunar surface that are never exposed to sunlight, such as water ice at the lunar poles in permanently shadowed craters. Further, in 2009, the Lunar Crater Observation and Sensing Satellite (LCROSS) spacecraft and Lunar Reconnaissance Orbiter (LRO) worked together to establish the presence of water ice. In 2018, the Moon Mineralogy Mapper (M3), aboard the ISRO’s Chandrayaan-1, allowed the creation of the first high-resolution map of water ice on the lunar surface.(NASA, Ices).

Mineral map of Moon. Confirmed water ice are blue. (Credit: ISRO/NASA/JPL-Caltech/Brown University/USGS)

Lunar TrailBlazer

However, is there really water on the Moon? There has been ample evidence that there is water on the Moon, dating back to the Clementine collision to more recent observations. Yet how much and where?

NASA’s NASA’s Lunar Trailblazer mission hopes to provide new insights into the lunar water cycle, so as to better understand the lunar water cycle and inform future human missions as to where supplies of water may be found and extracted as a resource. There will be two major sensing instruments. The High-resolution Volatiles and Minerals Moon Mapper (HVM3) is a JPL-developed imaging spectrometer that is sensitive to the spectral fingerprints of the different forms of water. The Lunar Thermal Mapper (LTM), being developed by the University of Oxford, will detail the temperature properties of the Moon’s surface.

Paragon In Situ Water Purifier

How will people and lunar spacecraft process and utilize this water? One new item of technology is Paragon Space Development Corporation’s Hydrogen Oxygen Production (IHOP) whose function is to produce purified water on the Moon from regolith-based resources. Then once water purified water is produced (after extraction), oxygen for breathing and fuel, and hydrogen for fuel can be produced from that water. This could save the tremendous expense of transporting water from the Earth to the Moon an improve the sustainability of a lunar facility.

What’s special about the technology? “Paragon is developing an innovative, contaminant robust subsystem that removes acidic and water soluble contaminants found within ISR-derived water on the Moon .. that could corrode systems, degrade

electrolyzer …performance, or present serious toxicity issues to humans” (Tewes et al., 2020). In addition, a ” Cold Trap and Paragon’s Nafion-based Ionomer-membrane Water Purification (IWP) technology provide the IHOP subsystem with broadband contaminant filtration, while an ammonia (NH3) scrubber and water polisher are optimized for a specific contaminant and final trace contaminant removal, respectively.” (Id.) Then this purified water can then be processed by a “water electrolyzer that can generate hydrogen and oxygen streams” (TechPort).

Applications for Earth Sustainability

There are locations one the Earth where water is scare, and what water does exist is full of toxic minerals. The Paragon technology could potentially help address that issue. Remote mining locations in semi-arid areas could be a use case.

Sources

Caltech, Lunar Trailblazer (web page). Last viewed September 18, 2024.

NASA TechPort, ISRU-ISRU Hydrogen Oxygen Production (IHOP-BAA). Last viewed on September 16, 2024).

NASA, Water & Ices on the Moon (webpage). Last viewed September 18, 2024.

P. Tewes, J. Holquist, C. Bower and L. Kelsey (2020), “ISRU-derived water purification and Hydrogen Oxygen Production (IHOP) Component Development“, Lunar Surface Science Workshop 2020 (LPI Contrib. No. 2241).