Figure 1—ESS mister nozzle (credit: NASA)

Spraying technology developed at the NASA Kennedy Space Center helps to overcome the challenges of microgravity on the use of aerial fluids in space while at the same time allows for more efficient spraying on Earth, helping to support more sustainable agriculture.

Watering Plants in Microgravity

Plants can be an important part of closing the life support loop in space. However, plants require water to live and grow. For a number of reasons, it is sometimes not possible to grow plants in Earth surface level gravity in space. Nor is such desirable when microgravity is required for research. Yet in microgravity, “even the simplest terrestrial plant watering methods face significant challenges when applied aboard spacecraft due to rogue bubbles, ingested gases, ejected droplets, and myriad unstable liquid jets.” (NASA, May 2025). Therefore, there needs to be better ways to water plants.

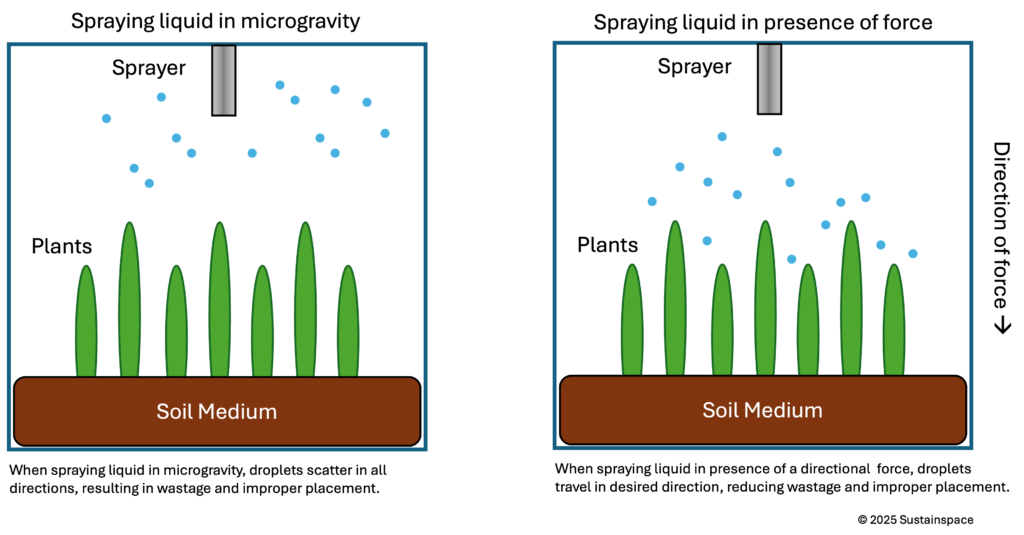

Regarding using spraying for delivering water and other chemicals on Earth, gravity directs liquid droplets from overhead sprayers downwards towards plants and soil (Figure 2, right). However, in microgravity environments in space, such as on the International Space station (ISS), there is no gravity to direct droplets, so they float around aimlessly (Figure 2, left), not getting to there they are needed and sometimes causing havoc elsewhere. Also, ineffective watering can lead to root to and other degenerative effects on plants.

Figure 2—spraying in microgravity (left) versus in presence of force such as gravity or electrostatic (right)

Spraying Technology

Commercially-available electrosprayers are generally large, air-assisted devices that require large amounts of liquid and electrical power. In contrast, folks at the NASA Kennedy Space Center (KSC) in Florida have developed a miniaturized electrosprayer system (Figure 1) which does not require compressed air, uses far less liquid, and concentrates the mist in an area less than 2 feet away” (NASA KTOP82).

“The pump provides a pressurized fluid at a constant flow rate through a nozzle at a low pressure, which sprays a fine mist of particles through a conductive metallic ring that is electrically charged by a voltage source. As the fluid particles pass through the center of the electrically charged ring, the particles themselves become charged, allowing them to attach to the roots of a target plant positioned at a selected distance away from the electrostatic plant watering system.” (Buhler and Wang, 2023). This approach restores a directional force to guide the water droplets, which provides a substitutional force for gravity, which restores the scenario shown in Figure 2, right.

This technology has found its way back to Earth for terrestrial agriculture uses, since “this sprayer may also enable the delivery of a precise liquid for terrestrial uses without relying on pressurized air.” (NASA KTOPS82). The electrosprayer technology has been licensed to Electrostatic Spraying Systems Inc. (ESS) of Watkinsville, Georgia, who manufactures electrostatic sprayers and equipment (ESS website). ESS uses this technology in its Maxcharge line, which are claimed to be much more efficient with the implication of using less chemicals by having improved spray coverage. (https://maxcharge.com/agriculture/

How This Fits Into The Sustainspace Model

This sprayer development and license is an example of the Sustainspace model in action. The sprayer solves a problem in space. It also provides parallel value for use on Earth. The license delivers revenue back to inventors and NASA centers to enable further space development. Identifying high value cases can help make the space program more financially sustainable while advancing environmental and societal sustainability on Earth.

References

Buhler, Charles R. and Jerry J. Wang, 2023, U.S. Patent 11,793,130, Electrosprayer Space Watering System.

Electrostatic Spraying Systems Inc. (ESS) company website, last viewed on 15 July 2025.

National Aeronautics and Space Administration (NASA), 2019, Distribution of Royalties and Other Payments Received by NASA from the Licensing or Assignment of Inventions, last viewed on 15 July 2025.

NASA, 2024, Miniaturized Electrospray System (KSC-TOPS-82), last viewed on 15 July 2025.

NASA, 2024, Tech Today: Spraying for Food Safety. Written by Andrew Wagner, last viewed on 15 July 2025.

NASA, 2025, Unearthly Plumbing Required for Plant Watering in Space. May 20, 2025, last viewed on 15 July 2025.

Further Reading

USDA, 2025, Growing Plants in Space, an interview with Ray Wheeler. Last Modified: 1/10/2025.

Sustainspace, 2018, Capillary structures could provide lower risk water recycling.

Sustainspace, 2014, NASA Targets Reduced Water Usage for Long Duration Missions.