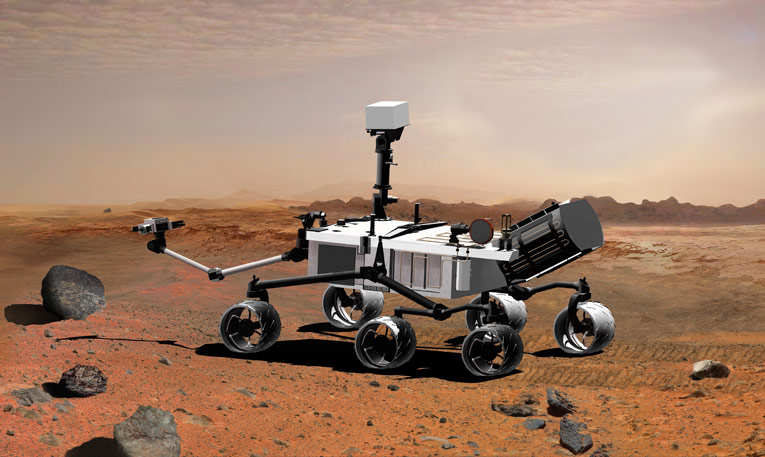

NASA Innovation Partnership Program Director Doug Comstock mentioned inXitu Inc. as an example of an innovative partnership with NASA at the August 5th CoLAB presentation in San Francisco. inXitu develops clean-tech air purifiers and portable material analyzers. The technology used in inXitu’s portable rock and mineral analyzer was chosen to fly on the Mars Science Laboratory rover (upper left) scheduled for launch in 2009.

inXitu has been developing a low-power, passively-cooled, grounded-anode miniature x-ray source to be deployed in miniaturized instruments for surface and subsurface exploration of the solar system. inXitu is also developing solutions targeted for identification and analysis in the areas of explosives, pharmaceuticals, forensics, art and archaeological materials. inXitu‘s new line of instruments will offer performance comparable to laboratory-sized systems with the benefit of portability, significantly reduced sample preparation and reduced cost.

inXitu is also developing a line of low-cost, electronic, pollution prevention devices (PPDs) that will preemptively eliminate nearly all toxic and noxious pollutants from ever entering the atmosphere. Originally designed for NASA as an air purifier for space station use, inXitu has re-engineered the PPDs to provide a simple low-cost device for tackling a wide array of pollutants. inXitu will introduce production units that will be fitted to manufacturing lines, residential air-conditioning units and anywhere highly purified air is needed. Hospitals can use them to provide a safe pathogen free environment for operating rooms and gas stations can fit them on storage tank vents to eliminate a major source of hydrocarbon release.

inXitu’s pollution prevention devices utilize an advanced electron beam source that cleanses air with high-energy electrons. Electron bombardment has proven to be effective in removing a wide spectrum of chemical and biological pollutants. Electron beam systems have a significant advantage over conventional volatile organic compound (VOC) and odor control technologies. The process requires less energy than other purification methods, generates no additional CO2, requires no additional reagents and does not produce any solid or hazardous waste. The breakthrough to meet the restrictive cost, weight and reliability requirements of commercial passenger aircraft and manned space exploration was to replace the thermionic cathode electron emitter with a carbon nanotube (CNT) field emission cathode.

NASA and inXitu each had technology the other party desired. This mutual interest formed the basis of a series of Small Business Innovative Research (SBIR) agreements. Such partnerships allow NASA to share the costs of creating new technology by helping to fund similar research by small businesses. SBIR agreements provide small businesses with critical early stage financing to research new technologies that may not be ripe enough to attract venture capital funding. Regarding the importance of SBIR agreements, inXitu “couldn’t have done it without them,” according to inXitu CEO Scott Snyder. inXitu has developed a series of innovations that has resulted in a corresponding series of new SBIR agreements. In one case, inXitu has even received a coveted SBIR Phase III award due the commercial and strategic importance of some of its technology.

NASA and inXitu each had technology the other party desired. This mutual interest formed the basis of a series of Small Business Innovative Research (SBIR) agreements. Such partnerships allow NASA to share the costs of creating new technology by helping to fund similar research by small businesses. SBIR agreements provide small businesses with critical early stage financing to research new technologies that may not be ripe enough to attract venture capital funding. Regarding the importance of SBIR agreements, inXitu “couldn’t have done it without them,” according to inXitu CEO Scott Snyder. inXitu has developed a series of innovations that has resulted in a corresponding series of new SBIR agreements. In one case, inXitu has even received a coveted SBIR Phase III award due the commercial and strategic importance of some of its technology.

Although the SBIR program is a good way to fund initial development of new technologies, a key barrier is the much greater financing often required for the technology to be developed for commercial use. NASA-initiated venture capital fund Red Planet Capital (aka Astrolabe Ventures) could help provide some of this funding, and other venture capital firms are beginning to be more accepting of environmental technologies.

Middle right: Mars Science Laboratory Chemistry & Mineralogy X-Ray Diffraction (CheMin). Images courtesy of the Jet Propulsion Laboratory.

(Originally published in 2008 in our Sustaianble Reentry blog).