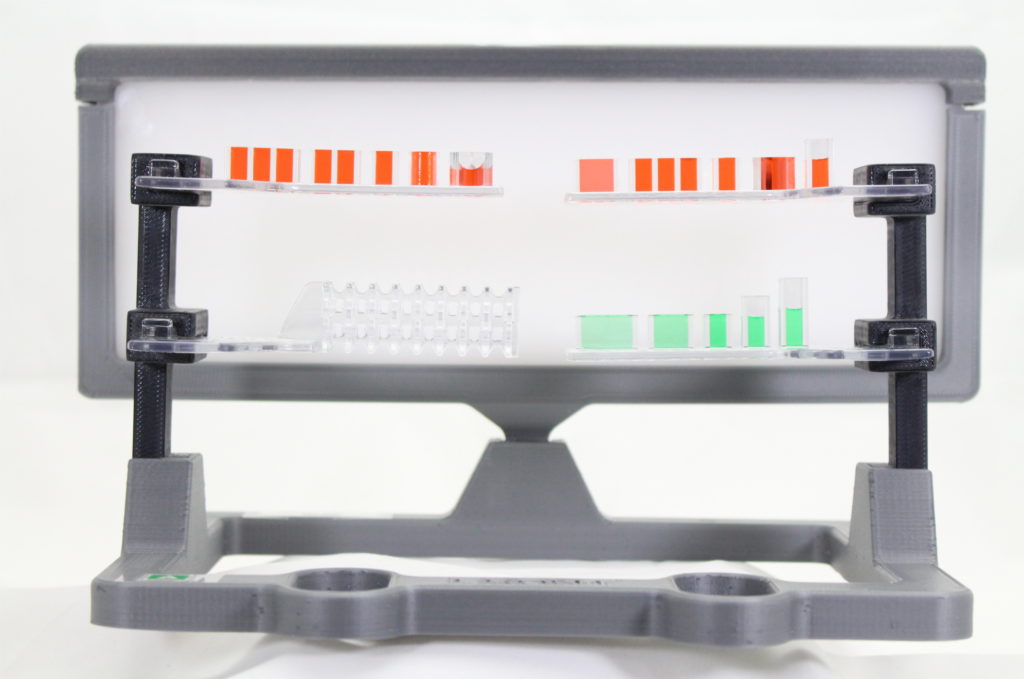

Capillary Evaporator prototype with transparent capillary structures filled with test fluids. Credits: IRPI LLC

Human use a lot of water for drinking and hygiene. Recycling is a key strategy to make the water that is launched into space last longer. Existing water recycling methods in space use harmful chemicals or considerable energy, and do not recycle 100% of the water. Reliability is crucial as well. So the search continues for new approaches to improve the water recycling process.

NASA is considering capillary structures for water recycling. Capillary action involves electrostatic forces literally pulling water through small tubes, similar to how drops of water will hang on objects despite the force of gravity pulling them away. NASA’s capillary structures investigation studies “a new method of water recycling and carbon dioxide removal using structures designed in specific shapes to manage fluid and gas mixtures in microgravity.” The capillary structures equipment is made up of small, 3-D printed geometric shapes and sizes sizes (see above image).